Thermomechanical Processing of ZX10 Magnesium Alloys

Understanding and optimizing hardness–corrosion trade-off via processing of biodegradable ZX10 Mg alloys

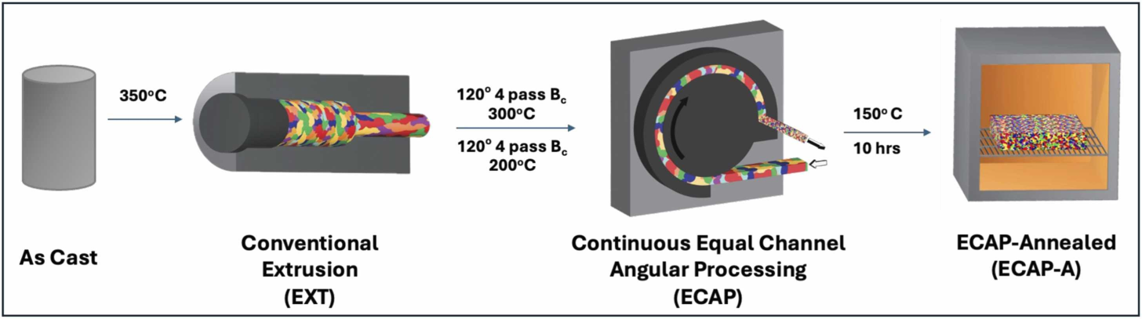

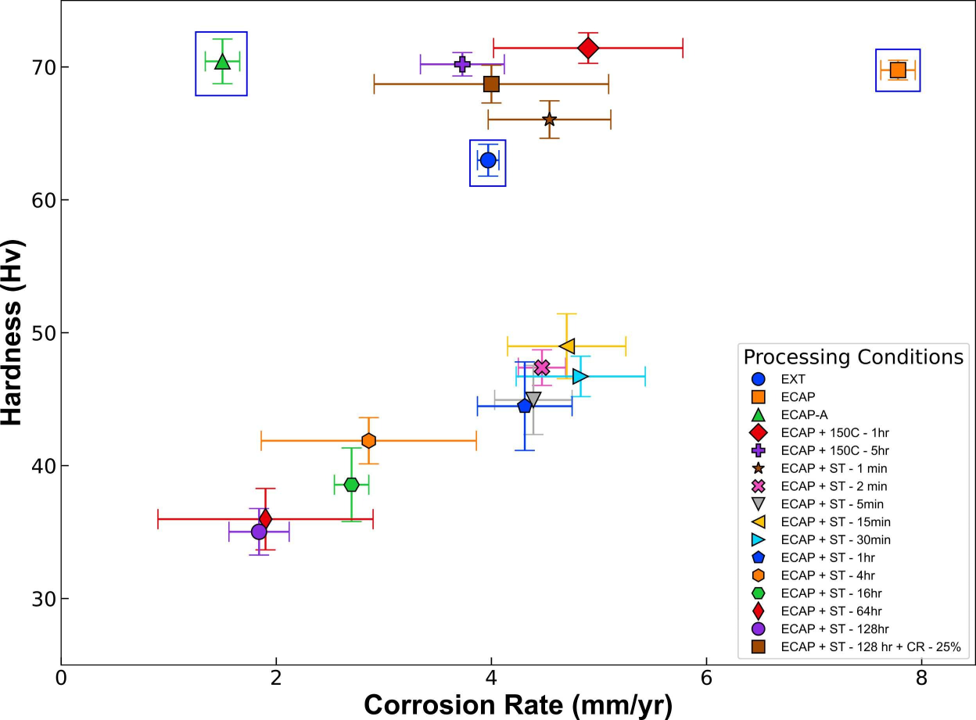

This project explores the effect of thermomechanical processing routes—including extrusion, ECAP, rolling annealing, and solution treatments—on the microstructure and performance of ZX10 magnesium alloys for biodegradable implant applications.

Our aim is to optimize the strength–corrosion trade-off, enabling better material performance for biomedical usage. This project is conducted in collaboration with Fort Wayne Metals, a leader in biomaterials processing and manufacturing.

Process Overview

Property Optimization: Hardness vs Corrosion

Collaboration

Publications

-

S. Raguraman, et al. “Simultaneous optimization of strength and bio-corrosion resistance in biodegradable ZX10 magnesium alloy via thermomechanical processing and annealing” Journal of Alloys and Compounds, 2025. https://doi.org/10.1016/j.jallcom.2025.180078

-

S. Raguraman, et al. “Impact of Thermo-Mechanical Processing on Structure–Property Relationships in Biodegradable ZX10 Mg Alloys.” In: Magnesium Technology 2024, Springer.

https://doi.org/10.1007/978-3-031-50240-8_40

This work lays the groundwork for our machine learning-based optimization project, where we integrate data-driven modeling to predict property outcomes and design better processing windows. See Machine Learning-Driven Optimization in Biodegradable Mg Alloys for more.