Machine Learning-Driven Optimization in Biodegradable Mg Alloys

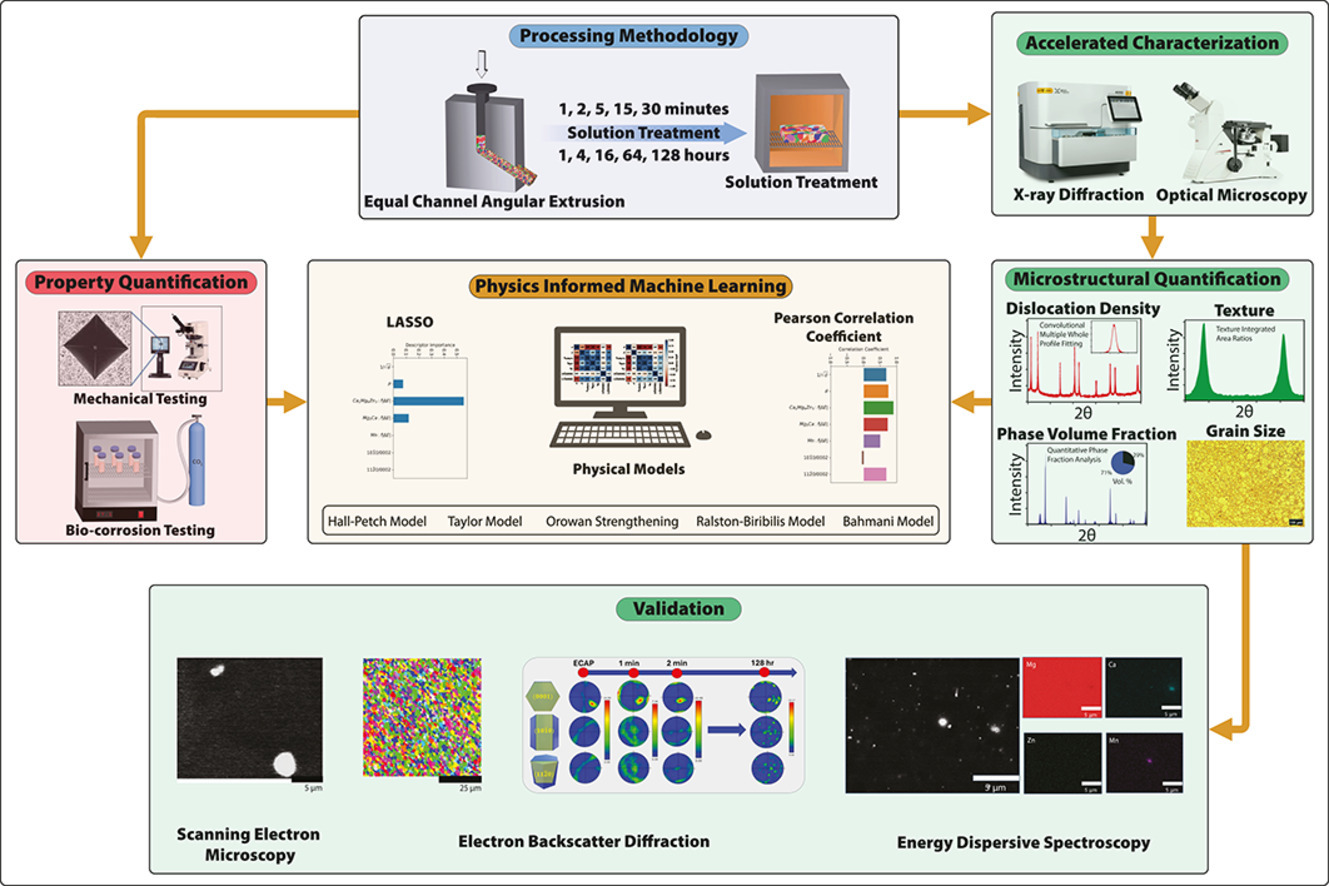

Using interpretable machine learning to optimize microstructure, processing, and properties of biodegradable magnesium alloys.

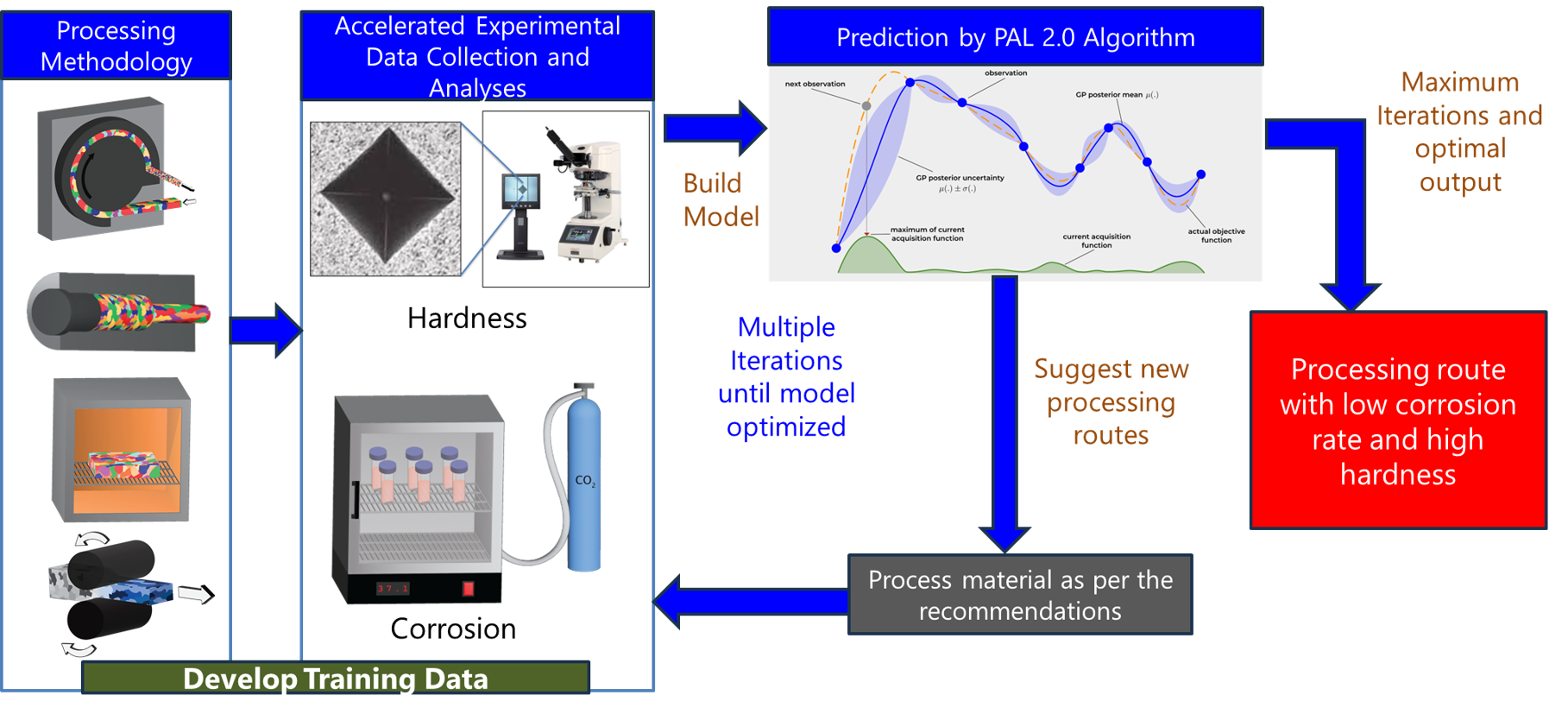

In this project, we develop a machine learning–guided strategy to simultaneously optimize corrosion resistance and hardness in biodegradable magnesium alloys, crucial for applications such as resorbable vascular scaffolds.

Working with (Prof. Paulette Clancy)[https://engineering.jhu.edu/faculty/paulette-clancy/] from Johns Hopkins University, Prof. Maitreyee Sharma Priyadharshini](https://www.aoe.vt.edu/people/faculty/maitreyee-sharma-priyadarshini.html) at Virginia Tech, and Mr. Adam Griebel at Fort Wayne Metals, we integrate physics-informed LASSO models and the PAL 2.0 Bayesian optimization framework to uncover structure–property linkages and suggest optimal processing paths.

Goals

- Accelerate discovery of microstructure–property relationships in Mg alloys.

- Optimize processing parameters (extrusion, ECAP, rolling, annealing) using Bayesian learning to minimize corrosion and maximize hardness.

- Translate laboratory discoveries to industry-relevant processing with Fort Wayne Metals.

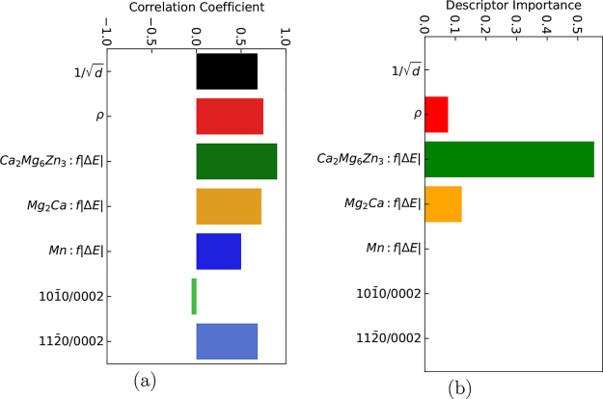

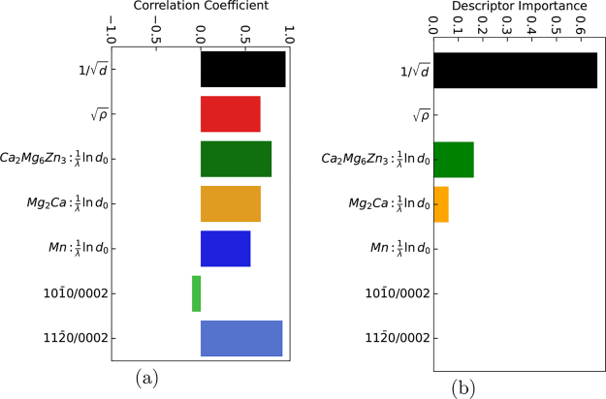

Interpretable ML with LASSO

We use physics-based LASSO regression to isolate key microstructural features controlling corrosion and hardness—going beyond black-box ML approaches. This work is supported by our publication:

- 📄 Machine learning-guided accelerated discovery of structure-property correlations in lean magnesium alloys for biomedical applications J. Magnes. Alloys, 2024

Establishing Corrosion Testing Standards

Given the lack of standardized corrosion protocols for biodegradable Mg alloys, we conducted a systematic evaluation of test media, buffering, and volume—essential for reliable ML training data. Our findings, published in JOM:

- 📄 Evaluating In-Vitro Corrosion Testing of ECAP-Processed Lean Magnesium Alloys: The Critical Role of Degradation Media Composition, Buffering, and Volume JOM, 2025:contentReference[oaicite:0]{index=0}

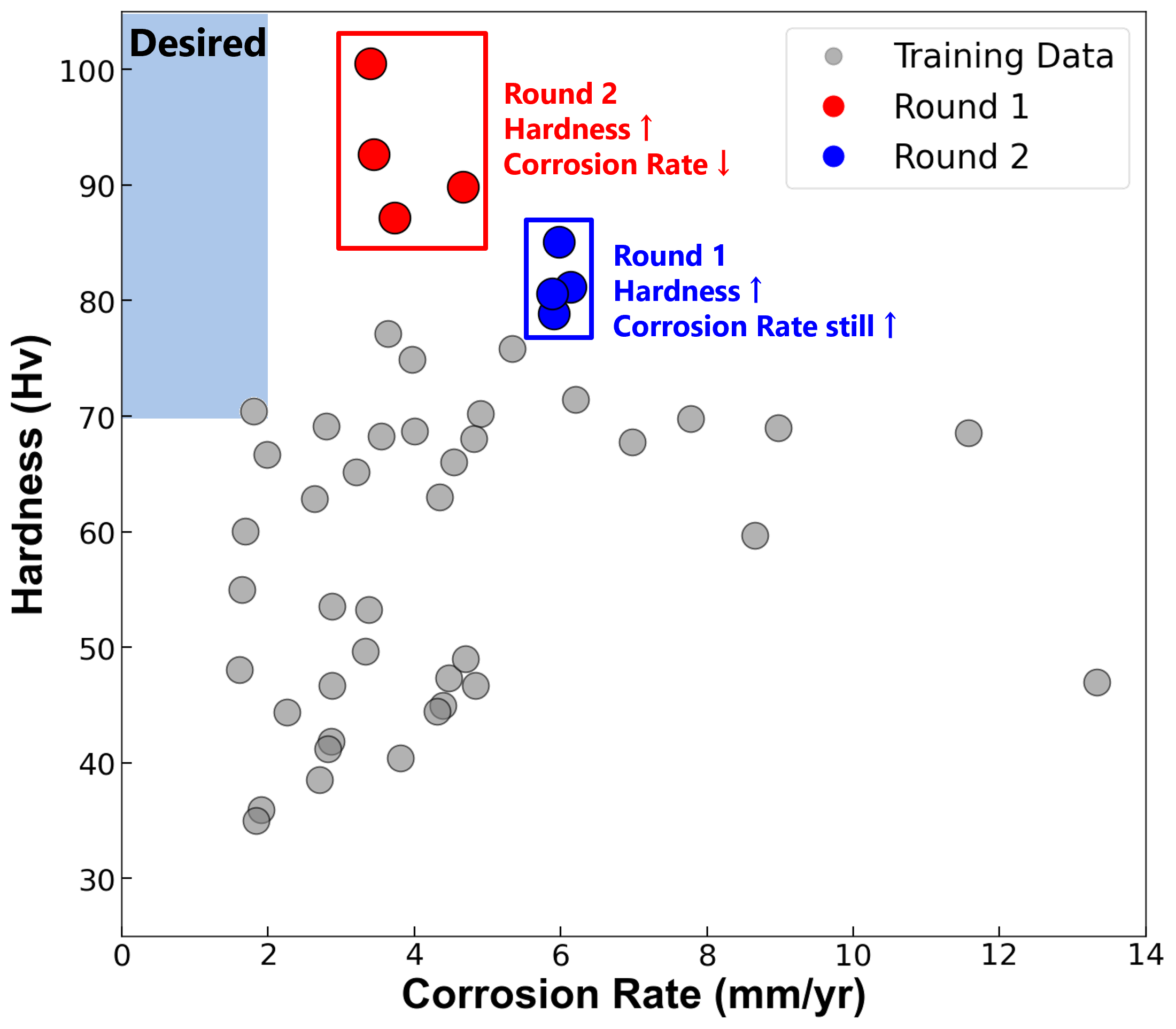

Process Optimization with PAL 2.0

We implemented PAL 2.0, a physics-aware Bayesian optimization framework, to iteratively explore processing pathways and optimize the tradeoff between hardness and corrosion. Unlike brute-force design of experiments, PAL learns from each round and proposes new experiments most likely to improve the property balance.

Preliminary Outcomes

- Structure–property links revealed through LASSO show processing effects on grain size, precipitate area, and GND density dominate performance.

- PAL 2.0 suggests new conditions not initially tested that outperform original processing routes.

- Corrosion standards and testing variability have been addressed to ensure robust training datasets for ML models.

Results were presented at TMS 2025, and a comprehensive manuscript integrating ML and experimental frameworks is in preparation.

Collaboration

In partnership with Mr. Adam Griebel from Fort Wayne Metals, Prof. Paulette Clancy from Johns Hopkins University, and Prof. Maitreyee Sharma Priyadharshini from Virginia Tech, this work explores scalable process development for orthopedic screw application.

References

-

S. Raguraman et al., Machine learning-guided accelerated discovery of structure-property correlations in lean magnesium alloys for biomedical applications, Journal of Magnesium and Alloys, 2024. https://doi.org/10.1016/j.jma.2024.06.008

-

S. Raguraman et al., Evaluating In-Vitro Corrosion Testing of ECAP-Processed Lean Magnesium Alloys: The Critical Role of Degradation Media Composition, Buffering, and Volume, JOM, 2025. https://doi.org/10.1007/s11837-025-07176-7