Recrystallization Behavior in Commercially Pure Titanium

Investigating the microstructure, texture, and mechanical evolution of cp-Ti during deformation and recrystallization.

This project was conducted during a research internship at the Laboratory of Texture and Related Studies, Department of Materials Engineering, Indian Institute of Science (IISc), Bangalore, under the guidance of Prof. Dr. Satyam Suwas and Dr. Gyan Shankar. The objective was to explore the development of crystallographic texture and mechanical property evolution in commercial purity titanium (cp-Ti) under cold rolling and subsequent recrystallization.

Objectives

- Understand how deformation and annealing affect texture and hardness in cp-Ti.

- Track the stages of recrystallization and associated microstructural evolution.

- Develop insights that support simulation validation and future alloy design.

Methods

- Mechanical Processing: Unidirectional cold rolling with 50% and 70% thickness reductions.

- Microstructural Characterization:

- Optical Microscopy and SEM for surface morphology.

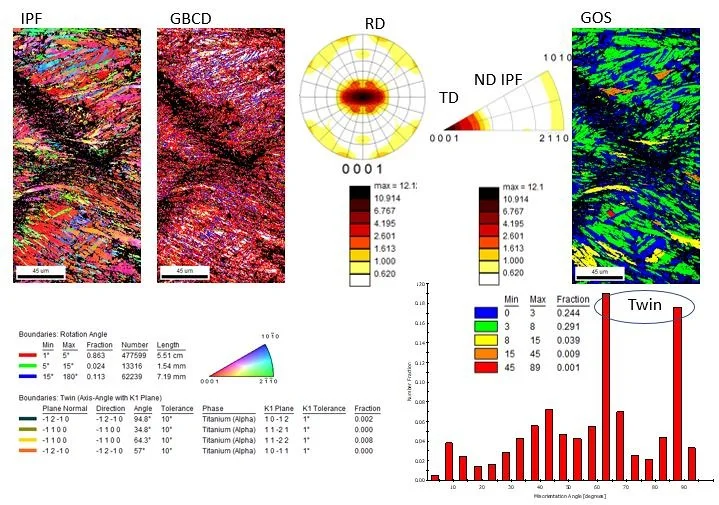

- EBSD for local orientation and recrystallization analysis.

- X-ray Diffraction for global texture quantification.

- Mechanical Testing: Microhardness mapping using Vickers hardness tester.

Outcomes

This study offered fundamental insights into recrystallization mechanisms and texture development in cp-Ti—critical for tailoring formability and strength in commercial applications. It also served as a benchmark for validating simulations.

Relevant Publication

- Gyan Shankar, Sreenivas Raguraman et al., Development of Recrystallization Texture in Commercially Pure Titanium: Experiments and Simulation,

JOM, 72, 2, 758–767 (2020). https://doi.org/10.1007/s11837-020-04447-3