publications

publications by categories in reversed chronological order. generated by jekyll-scholar.

2025

-

Microstructure regulates early-stage corrosion behavior and systemic aluminum fate in biodegradable Mg–Al alloys: Integrated in-vitro and in-vivo insightsSreenivas Raguraman, Mitchell Connon, Camryn Byrum, and 6 more authorsActa Biomaterialia, Nov 2025

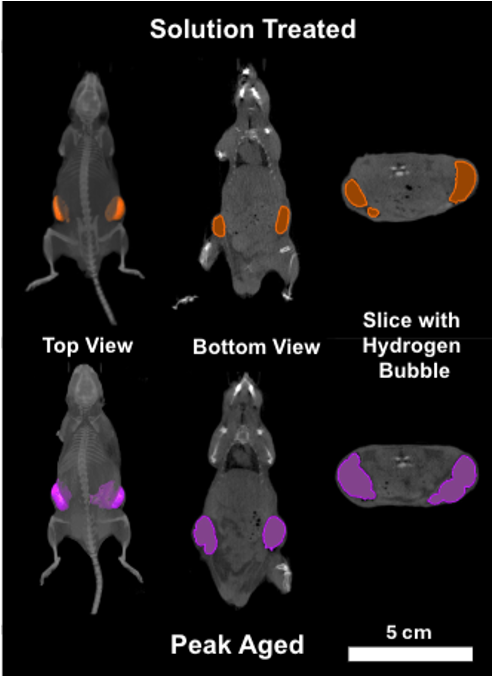

Microstructure regulates early-stage corrosion behavior and systemic aluminum fate in biodegradable Mg–Al alloys: Integrated in-vitro and in-vivo insightsSreenivas Raguraman, Mitchell Connon, Camryn Byrum, and 6 more authorsActa Biomaterialia, Nov 2025Magnesium–aluminum (Mg–Al) alloys are promising candidates for biodegradable implants, offering a favorable balance of mechanical strength and corrosion resistance. However, the release and systemic fate of aluminum (Al) during alloy degradation remain poorly understood, especially in relation to their microstructure. In this study, we investigate the role of β-Mg17Al12 precipitates in governing Al release from Mg–9Al alloys under both in-vitro and in-vivo conditions. In-vitro immersion testing revealed that peak‑aged (PA) samples, containing a high density of β-Mg17Al12 precipitates, exhibited accelerated pitting corrosion and higher total Al release compared to solution‑treated (ST) samples. In contrast, in-vivo subcutaneous implantation demonstrated the opposite trend regarding Al release with ST implants yielding higher systemic Al ion levels, whereas PA implants retained more particulate β-Mg17Al12 and corrosion products at the implantation site. This behavior is attributed to differences in Al speciation and mobilization, with Al from ST alloys releasing primarily in solute form and Al from PA alloys predominantly present as highly elongated precipitate fragments that remained localized and resisted systemic transport. These findings underscore that microstructure influences not only corrosion kinetics but also the bioavailability and physiological distribution of Al degradation products. This work provides a framework for designing Mg‑based alloys that balance mechanical performance with favorable physiological clearance, advancing the development of safe and effective biodegradable implants.

-

A call to elevate the role of processing in AI-driven materials designSreenivas Raguraman, Adam Griebel, Maitreyee Sharma Priyadharshini, and 2 more authorsNature Reviews Materials, Oct 2025

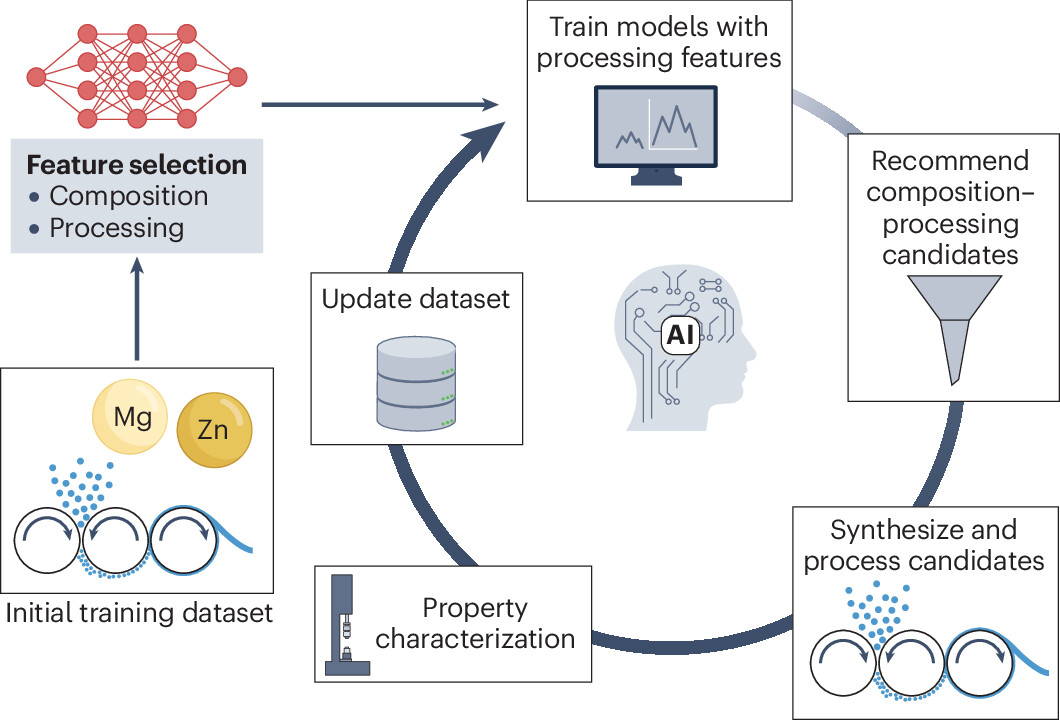

A call to elevate the role of processing in AI-driven materials designSreenivas Raguraman, Adam Griebel, Maitreyee Sharma Priyadharshini, and 2 more authorsNature Reviews Materials, Oct 2025Despite transformative advances in materials discovery, real-world performance still hinges on an often-overlooked variable: processing. To bridge the gap between discovery and deployment, processing must be elevated from an afterthought to a central pillar in design frameworks, data generation and machine learning.

-

Enhancing the Hardness–Corrosion Balance in Lean Mg–Ca Alloys via Post-Extrusion Thermomechanical ProcessingAndrew Kim, Sreenivas Raguraman, Adam J Griebel, and 1 more authorSep 2025Accepted in TMS Supplemental Proceedings 2026

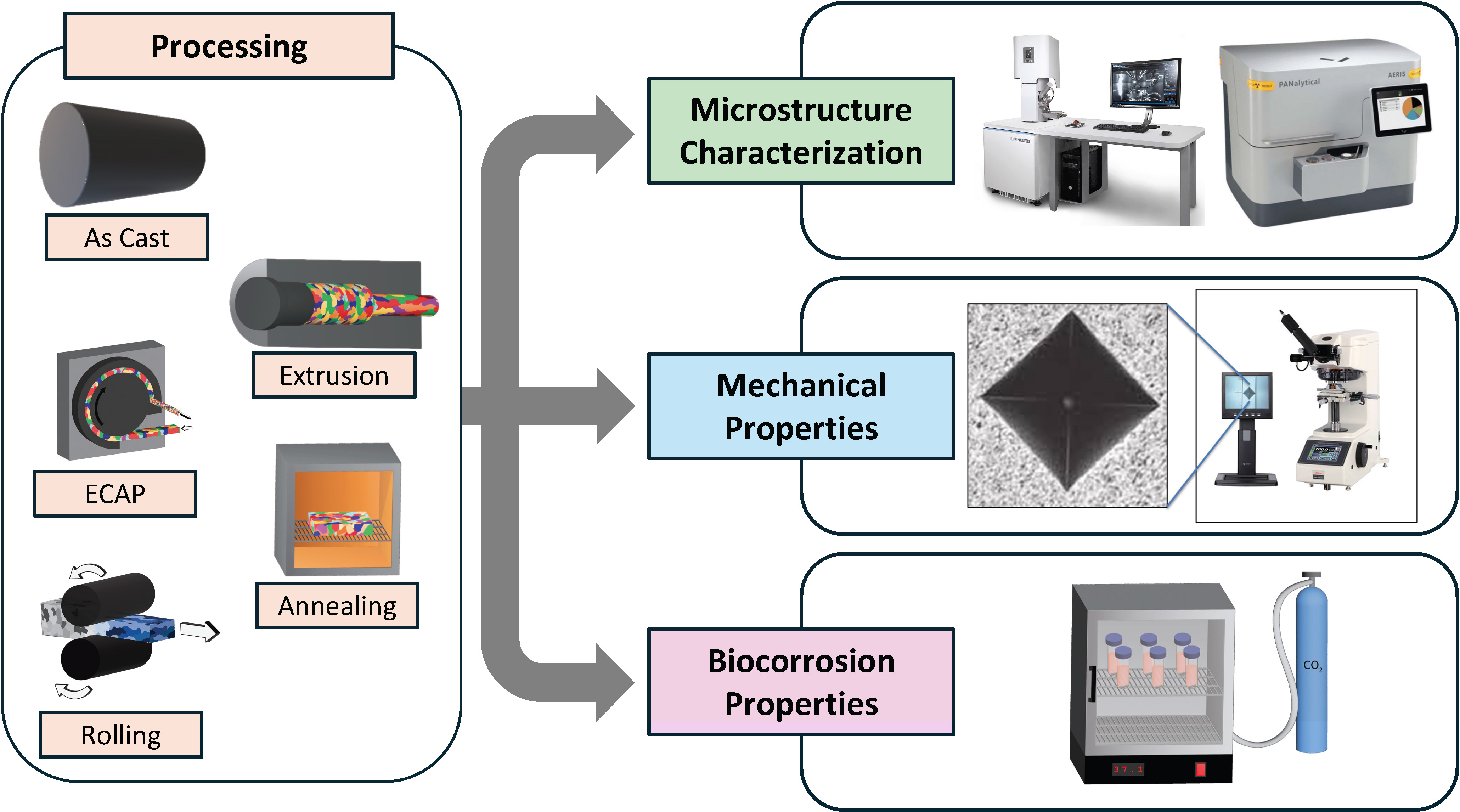

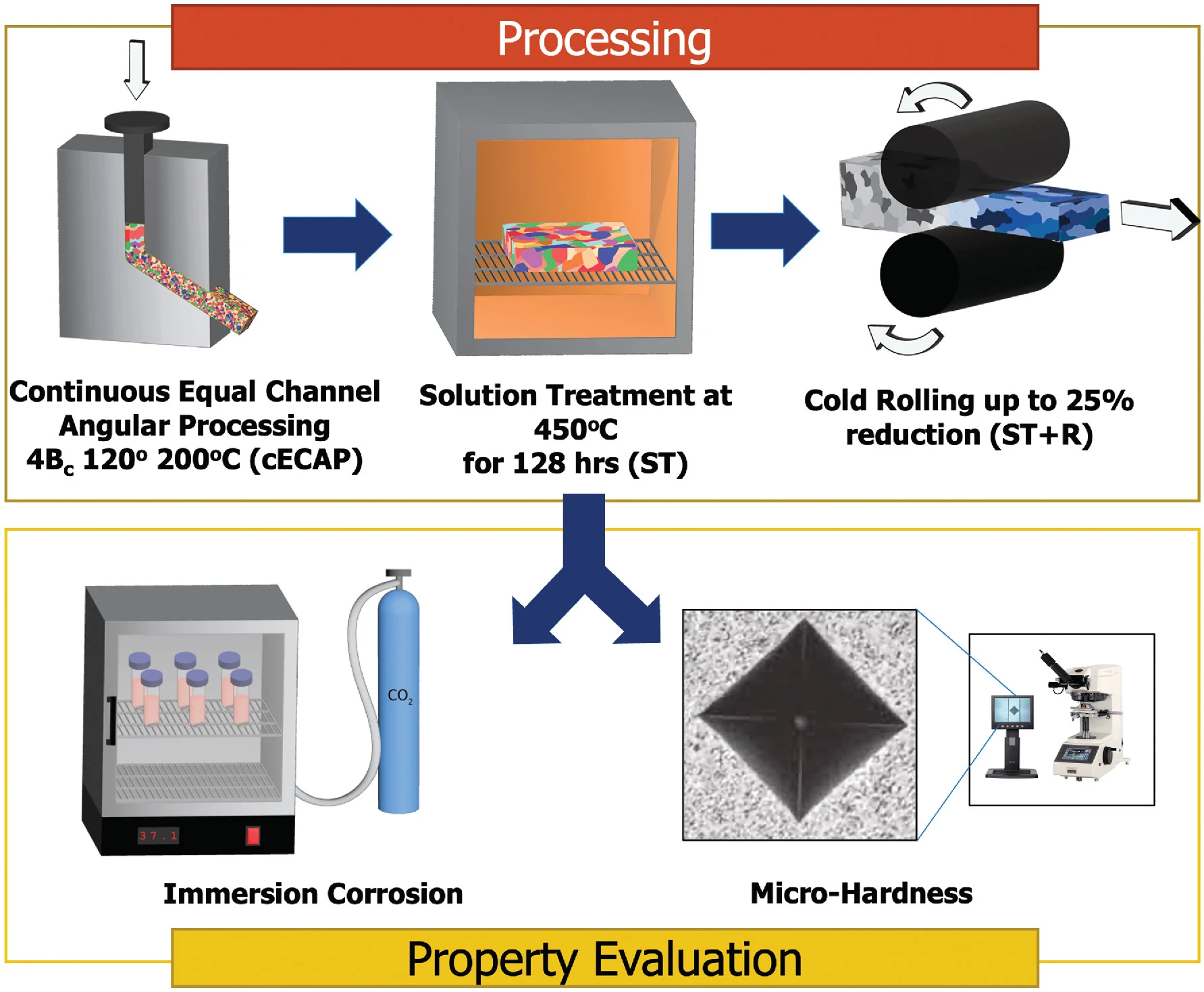

Enhancing the Hardness–Corrosion Balance in Lean Mg–Ca Alloys via Post-Extrusion Thermomechanical ProcessingAndrew Kim, Sreenivas Raguraman, Adam J Griebel, and 1 more authorSep 2025Accepted in TMS Supplemental Proceedings 2026Lean magnesium–calcium (Mg–Ca) alloys are promising for biodegradable orthopedic implants because their limited alloying content suppresses corrosion while maintaining biocompatibility. The key challenge is achieving high strength without sacrificing corrosion resistance. Conventional extrusion at elevated temperatures prevents cracking but delivers only modest grain refinement. With the minimal precipitation hardening available from dilute Ca additions, the resulting mechanical performance remains inadequate. To overcome this, we systematically investigate post-extrusion thermomechanical processing routes, including equal channel angular pressing (ECAP), rolling, and heat treatments, to optimize microstructure, hardness, and degradation response. Among the pathways explored, extrusion followed by ECAP, rolling, and annealing offers the most effective balance of hardness and corrosion resistance. These results demonstrate that process design can overcome the limited strengthening capacity of lean Mg–Ca alloys and advance their viability as next-generation biodegradable implant materials.

-

Machine Learning-Assisted Analysis of Combustion and Ignition in As-milled and Annealed Al/Zr Composite PowdersMichael R. Flickinger, Sreenivas Raguraman, Amee L. Polk, and 6 more authorsSep 2025Accepted in Combustion and Flame

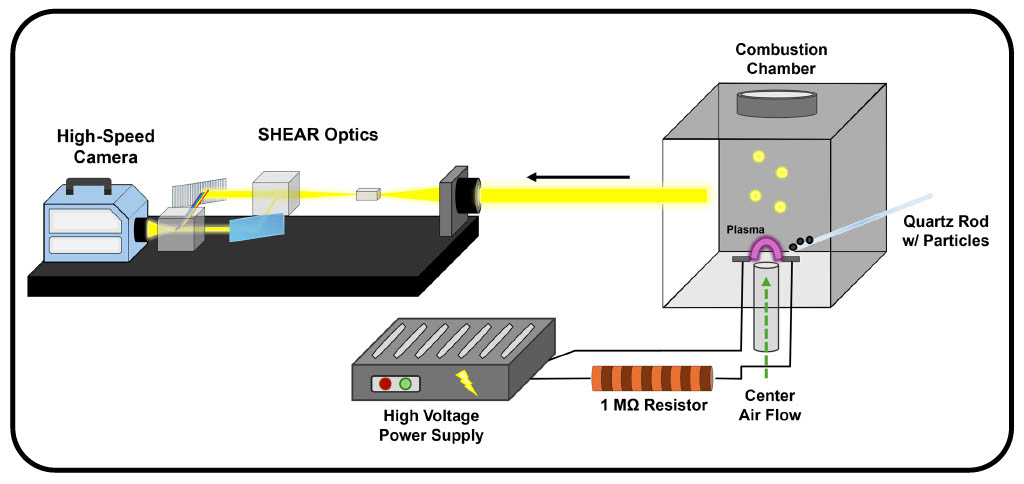

Machine Learning-Assisted Analysis of Combustion and Ignition in As-milled and Annealed Al/Zr Composite PowdersMichael R. Flickinger, Sreenivas Raguraman, Amee L. Polk, and 6 more authorsSep 2025Accepted in Combustion and FlameMicron-scale metal-based composite powders are promising for energetic applications due to their tailored ignition and combustion properties. In particular, ball-milled Al/Zr composites exhibit lower ignition thresholds than pure aluminum, driven by exothermic intermetallic formation reactions and have demonstrated enhanced combustion properties. However, the extent to which this heat release governs ignition and combustion remains unclear, especially as it is progressively removed through annealing. To systematically investigate this effect, we synthesized Al/Zr powders (3Al:Zr, Al:Zr, and Al:3Zr at%) via ball milling, annealed them in argon up to 1000 °C to partially complete the formation reactions, and characterized their ignition and combustion behavior. Ignition thresholds were measured using a hot wire method across different environments, while high-speed hyperspectral imaging tracked single-particle burn durations and temperatures. A convolutional neural network (CNN)-based method was developed to quantify the frequency of microexplosions. Results show that annealing—by reducing the available reaction heat—increases ignition thresholds, most significantly for Al-rich compositions. In contrast, Zr-rich powders exhibit little change in ignition threshold because oxidation aids ignition. Despite removing the available heat that drives ignition, average combustion temperatures range from 2400-3000 K and increase with annealing for Al- and Zr-rich powders. Average maximum temperatures are 100-400 K higher. The frequency of microexplosions remains high (>46%) and increases with annealing for all but the Al-rich powders. These findings suggest that while homogeneous Al/Zr powders (e.g., atomized) may exhibit higher ignition thresholds, they can achieve comparable combustion performance once ignited.

-

Simultaneous optimization of strength and bio-corrosion resistance in biodegradable ZX10 magnesium alloy via thermomechanical processing and annealingSreenivas Raguraman, Andrew Kim, Tunde Ayodeji, and 4 more authorsJournal of Alloys and Compounds, Apr 2025

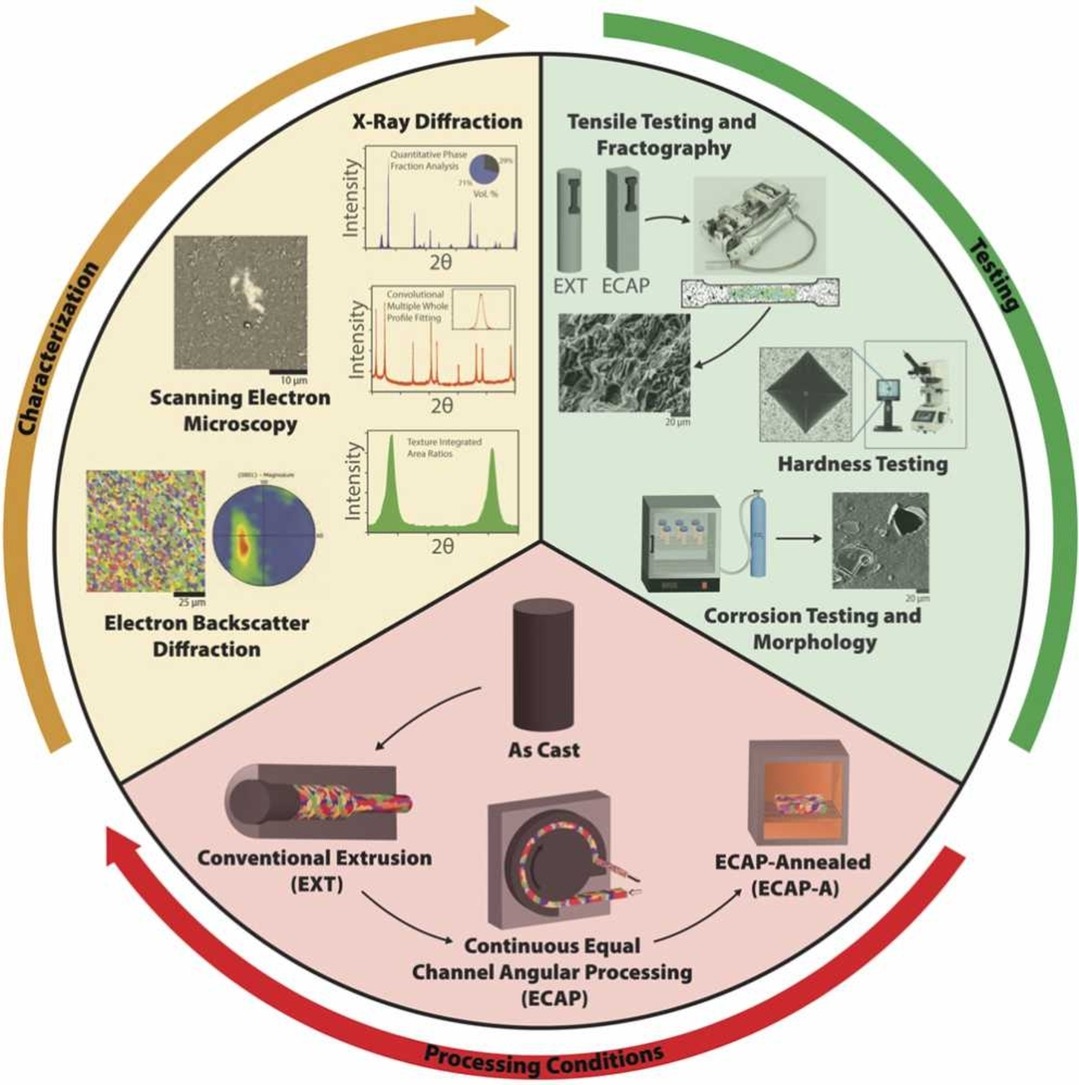

Simultaneous optimization of strength and bio-corrosion resistance in biodegradable ZX10 magnesium alloy via thermomechanical processing and annealingSreenivas Raguraman, Andrew Kim, Tunde Ayodeji, and 4 more authorsJournal of Alloys and Compounds, Apr 2025Magnesium alloys are increasingly recognized as promising materials for biodegradable implants due to their low density, biocompatibility, and favorable mechanical properties. However, achieving a balance between mechanical strength and bio-corrosion resistance remains a critical challenge. This study systematically investigates the effects of three thermomechanical processing routes—extrusion (EXT), Equal Channel Angular Pressing (ECAP), and ECAP followed by annealing at 150oC for 10 h (ECAP-A)—on the ZX10 magnesium alloy. EXT produced coarse grains and moderate mechanical and corrosion performance. ECAP refined the grain structure and reduced the Mg2Ca phase, leading to an 80 % increase in hardness, improved yield strength, and enhanced ductility, but at the cost of a doubled corrosion rate due to high dislocation density. ECAP-A mitigated this drawback, reducing the corrosion rate to 1.50 mm/year while maintaining a high yield strength ( \textgreater 200 MPa). This improvement was driven by a uniform distribution of the Ca2Mg6Zn3 phase, further dissolution of the Mg2Ca phase, and reduced dislocation density. These findings establish ECAP-A as an effective strategy to simultaneously optimize strength and bio-corrosion resistance, advancing the ZX10 magnesium alloy as a promising material for biodegradable implants.

-

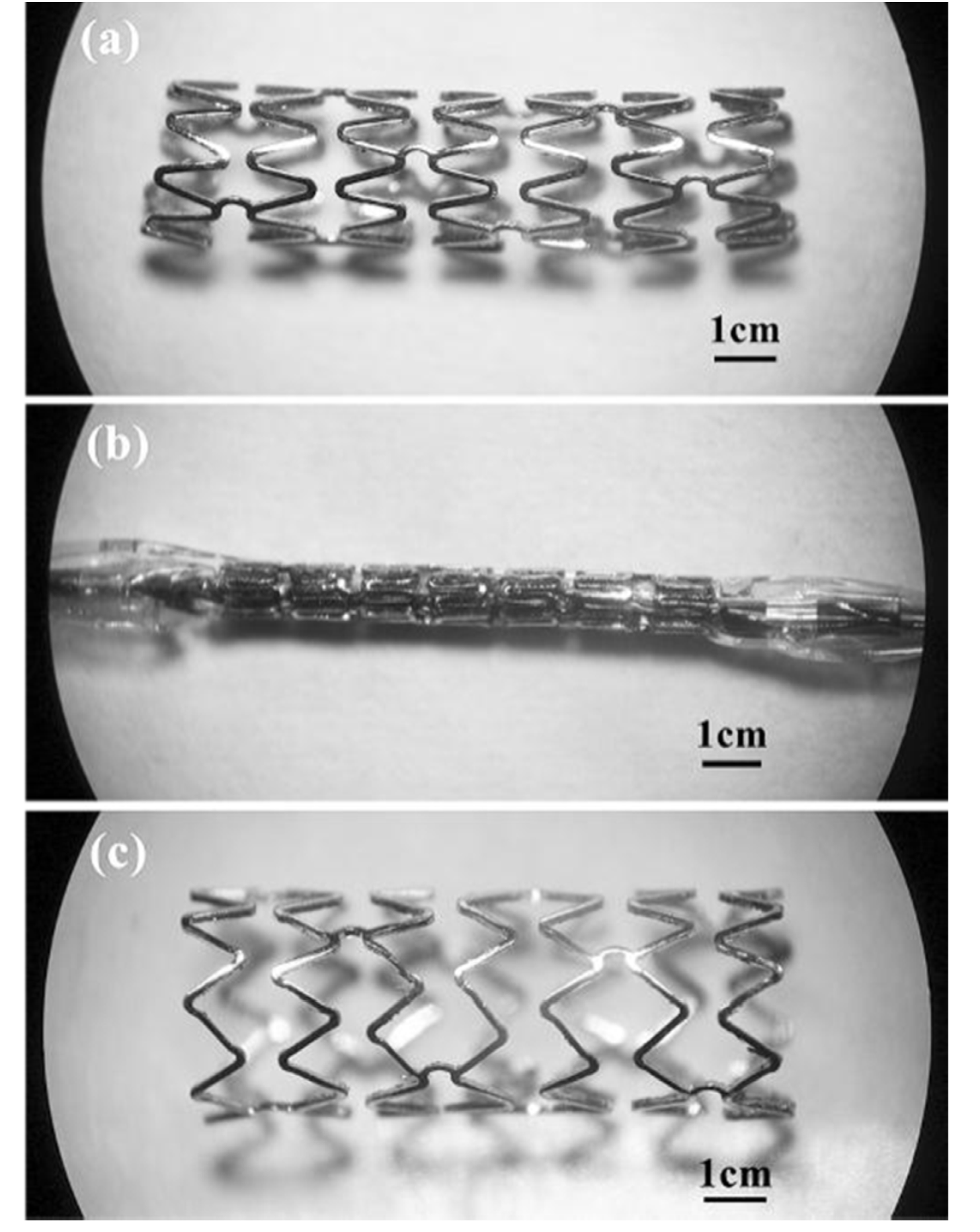

Role of microstructure, corrosion, and pit geometry in governing strength and ductility loss in biodegradable magnesium alloy wiresBeril Ulugun, Sreenivas Raguraman, Nana Barimah Osei-Owusu, and 4 more authorsNov 2025

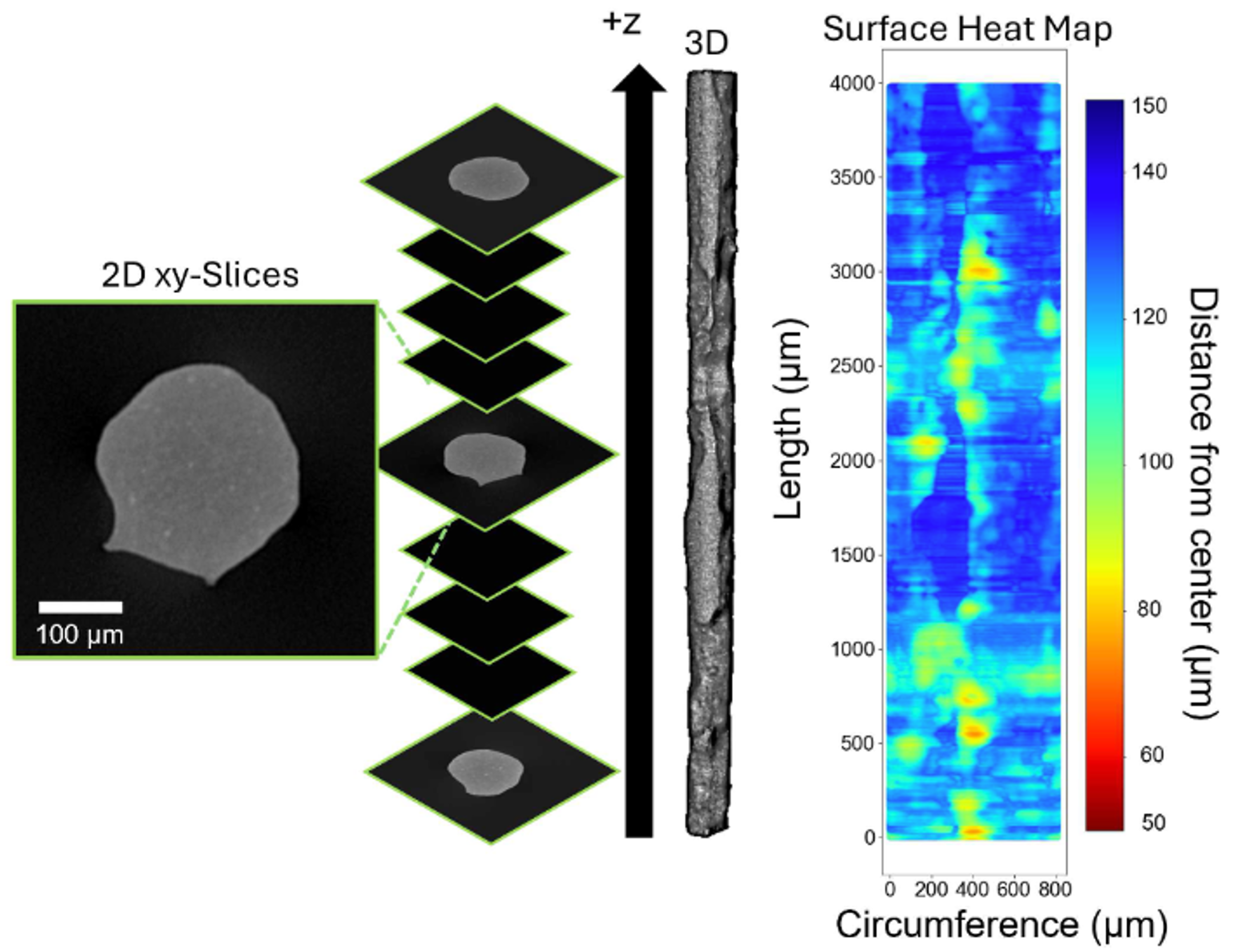

Role of microstructure, corrosion, and pit geometry in governing strength and ductility loss in biodegradable magnesium alloy wiresBeril Ulugun, Sreenivas Raguraman, Nana Barimah Osei-Owusu, and 4 more authorsNov 2025Biodegradable magnesium (Mg) wires offer a promising route for fabricating complex medical implants such as stents, cables, and scaffolds. Compared to additive manufacturing or laser cutting, wire-based processing enables high-throughput production of flexible structures with minimal thermal distortion and improved microstructural control. However, the small diameter of Mg wires makes them especially vulnerable to corrosion, as even low corrosion rates result in a higher percentage of material loss relative to volume, which can severely compromise mechanical integrity. This study compares WE43 and ZXM100 Mg wires (300 µm diameter) processed by cold drawing and annealing to evaluate how alloy-specific microstructures influence corrosion behavior and mechanical degradation. Using SEM, EBSD, u-CT, and tensile testing, we examine the role of precipitate type, size, and distribution in governing pit morphology and post-immersion mechanical performance. WE43 exhibits uniform axial pitting associated with elongated Mg41Nd5 precipitates, resulting in steady degradation and near-complete loss of ductility. ZXM100 shows heterogeneous radial pitting around coarse Mg2Ca precipitates, often causing early failure. However, surviving ZXM100 wires retain greater strength and ductility than WE43. After 7 days of immersion, WE43 lost 59% of strength and 98% of ductility, while unfractured ZXM100 wires lost 42% and 87%, respectively. These findings underscore the importance of alloy-specific microstructural control for biomedical Mg wire design.

-

Evaluating In-Vitro Corrosion Testing of ECAP-Processed Lean Magnesium Alloys: The Critical Role of Degradation Media Composition, Buffering, and VolumeSreenivas Raguraman, Beril Ulugun, Tunde Ayodeji, and 3 more authorsJOM, Feb 2025

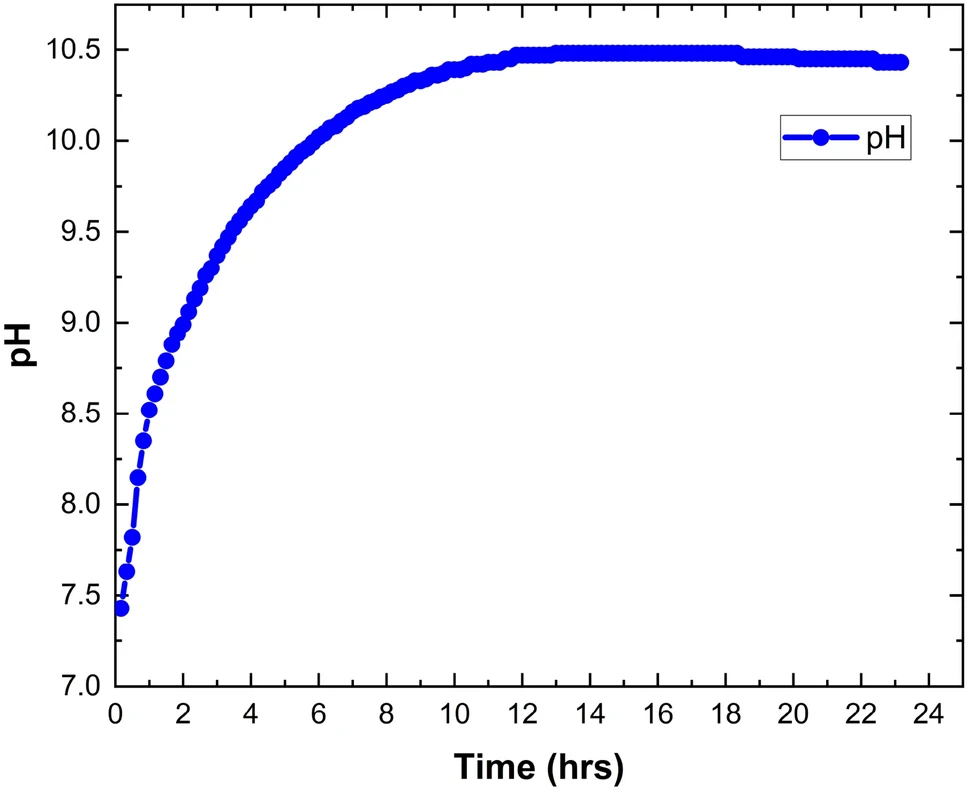

Evaluating In-Vitro Corrosion Testing of ECAP-Processed Lean Magnesium Alloys: The Critical Role of Degradation Media Composition, Buffering, and VolumeSreenivas Raguraman, Beril Ulugun, Tunde Ayodeji, and 3 more authorsJOM, Feb 2025Biodegradable magnesium (Mg) alloys are promising for biomedical implants due to their favorable mechanical properties and safe degradation within the human body. However, the rapid corrosion of Mg remains a challenge, necessitating a deeper understanding of its behavior in physiological environments. This study evaluates the in vitro corrosion performance of a lean Mg-Zn-Ca alloy processed via equal channel angular pressing to refine the grain size and enhance the mechanical properties. Corrosion behavior was assessed in Hank’s balanced salt solution (HBSS), Earle’s balanced salt solution (EBSS) buffered with 5% \\{}hbox {CO}}_{2}\ CO 2 , and Dulbecco’s modified eagle medium (DMEM) with 10% fetal bovine serum (FBS) buffered with 5% \\{}hbox {CO}}_{2}\ CO 2 . Significant differences in corrosion rates were observed across media, with HBSS exhibiting the lowest rates and EBSS the highest. DMEM with 10% FBS produced intermediate corrosion rates under conditions that closely mimic physiological environments. The effect of \\{}hbox {CO}}_{2}\ CO 2 buffering in HBSS was also evaluated, demonstrating enhanced pH control below 7.5, which simulates physiological pH. Additionally, increasing the volume of HBSS, both with and without \\{}hbox {CO}}_{2}\ CO 2 buffering, led to reduced corrosion rates and greater pH stabilization. These results demonstrate how testing conditions influence corrosion rates and pH stability, advancing our understanding of biodegradable Mg alloys for biomedical applications.

2024

-

Impact of Thermo-Mechanical Processing on Structure–Property Relationships for the Biodegradable ZX10 Mg AlloySreenivas Raguraman, Ryan McGovern, Andrew Kim, and 5 more authorsIn Magnesium Technology 2024, Feb 2024

Impact of Thermo-Mechanical Processing on Structure–Property Relationships for the Biodegradable ZX10 Mg AlloySreenivas Raguraman, Ryan McGovern, Andrew Kim, and 5 more authorsIn Magnesium Technology 2024, Feb 2024Magnesium alloys offer immense potential as intelligent alternatives to traditional implant materials due to their inherent degradability, biocompatibility, and exceptional mechanical properties. However, their rapid deterioration hinders their practical applications, compromising their mechanical integrity. This study addresses this challenge by investigating the effects of thermo-mechanical processing, including extrusion, cECAP, rolling, and annealing, on the high-strength, dilute ZX10 Mg alloy. By subjecting the alloy to over thirty processing conditions, we identify an optimal combination of high-strength and low-corrosion rates. Simple characterization techniques like XRD, optical microscopy, and SEM were employed to rapidly evaluate the microstructural changes post-processing. The findings identify that grain boundary and strain hardening play pivotal roles in enhancing hardness, while factors such as texture, dislocation density, and precipitates impact corrosion significantly. This comprehensive investigation provides valuable insights into processing-structure–property relationships for Mg alloys, paving the way for developing superior biodegradable implant materials.

-

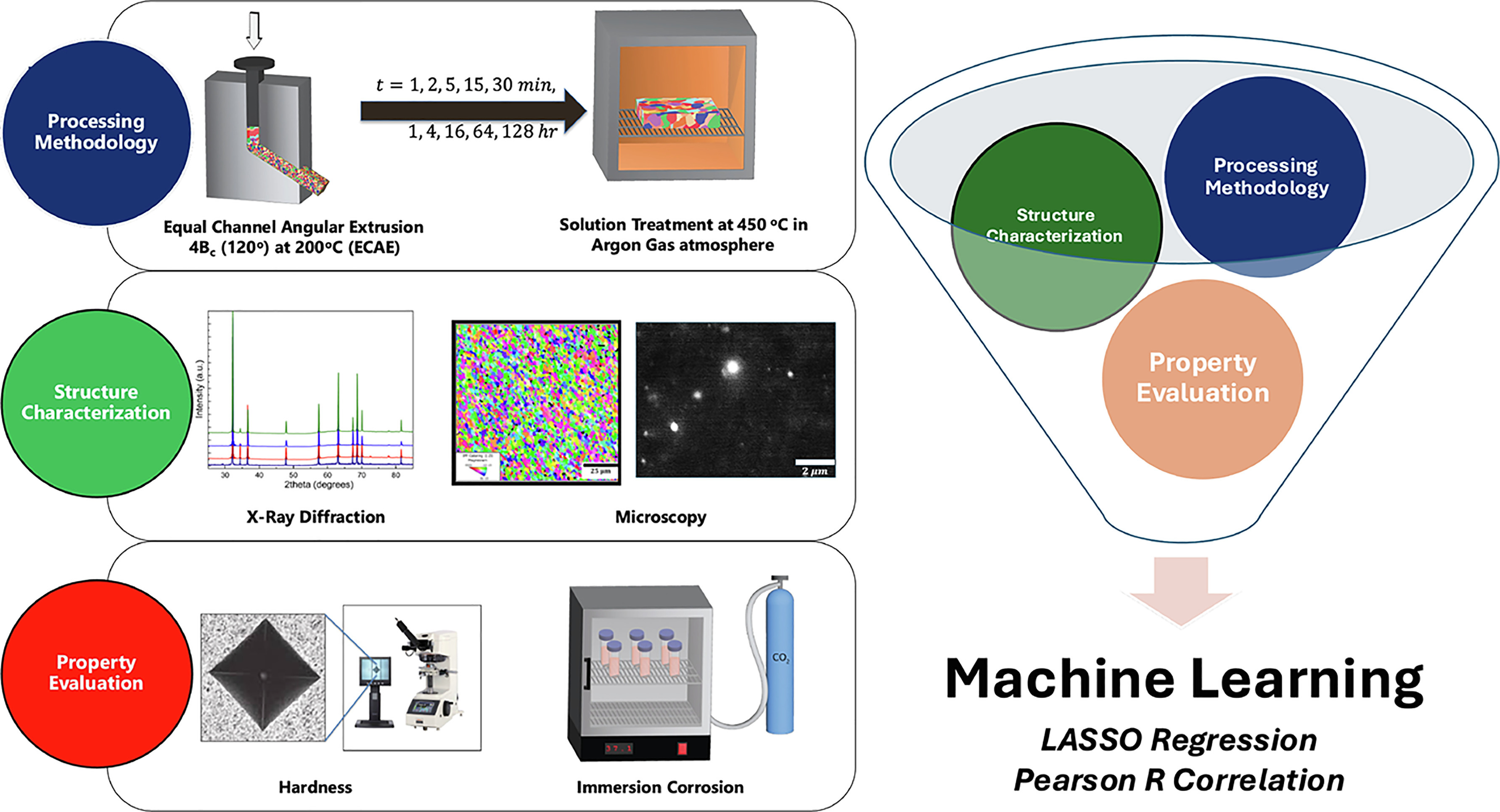

Machine learning-guided accelerated discovery of structure-property correlations in lean magnesium alloys for biomedical applicationsSreenivas Raguraman, Maitreyee Sharma Priyadarshini, Tram Nguyen, and 5 more authorsJournal of Magnesium and Alloys, Jun 2024

Machine learning-guided accelerated discovery of structure-property correlations in lean magnesium alloys for biomedical applicationsSreenivas Raguraman, Maitreyee Sharma Priyadarshini, Tram Nguyen, and 5 more authorsJournal of Magnesium and Alloys, Jun 2024Magnesium alloys are emerging as promising alternatives to traditional orthopedic implant materials thanks to their biodegradability, biocompatibility, and impressive mechanical characteristics. However, their rapid in-vivo degradation presents challenges, notably in upholding mechanical integrity over time. This study investigates the impact of high-temperature thermal processing on the mechanical and degradation attributes of a lean Mg-Zn-Ca-Mn alloy, ZX10. Utilizing rapid, cost-efficient characterization methods like X-ray diffraction and optical microscopy, we swiftly examine microstructural changes post-thermal treatment. Employing Pearson correlation coefficient analysis, we unveil the relationship between microstructural properties and critical targets (properties): hardness and corrosion resistance. Additionally, leveraging the least absolute shrinkage and selection operator (LASSO), we pinpoint the dominant microstructural factors among closely correlated variables. Our findings underscore the significant role of grain size refinement in strengthening and the predominance of the ternary Ca2Mg6Zn3 phase in corrosion behavior. This suggests that achieving an optimal blend of strength and corrosion resistance is attainable through fine grains and reduced concentration of ternary phases. This thorough investigation furnishes valuable insights into the intricate interplay of processing, structure, and properties in magnesium alloys, thereby advancing the development of superior biodegradable implant materials.

2022

-

Current Status and Outlook of Temporary Implants (Magnesium/Zinc) in Cardiovascular ApplicationsSomasundaram Prasadh, Sreenivas Raguraman, Raymond Wong, and 1 more authorMetals, Jun 2022

Current Status and Outlook of Temporary Implants (Magnesium/Zinc) in Cardiovascular ApplicationsSomasundaram Prasadh, Sreenivas Raguraman, Raymond Wong, and 1 more authorMetals, Jun 2022Medical application materials must meet multiple requirements, and the designed material must mimic the structure, shape. and support the formation of the replacing tissue. Magnesium (Mg) and Zinc alloys (Zn), as a “smart” biodegradable material and as “the green engineering material in the 21st century”, have become an outstanding implant material due to their natural degradability, smart biocompatibility, and desirable mechanical properties. Magnesium and Zinc are recognized as the next generation of cardiovascular stents and bioresorbable scaffolds. At the same time, improving the properties and corrosion resistance of these alloys is an urgent challenge. particularly to promote the application of magnesium alloys. A relatively fast deterioration rate of magnesium-based materials generally results in premature mechanical integrity compromise and local hydrogen build-up, resulting in restricted applicability. This review article aims to give a comprehensive comparison between Zn-based alloys and Mg-based alloys, focusing primarily on degradation and biocompatibility for cardiovascular applications. The recent clinical trials using these biodegradable metals have also been addressed.

-

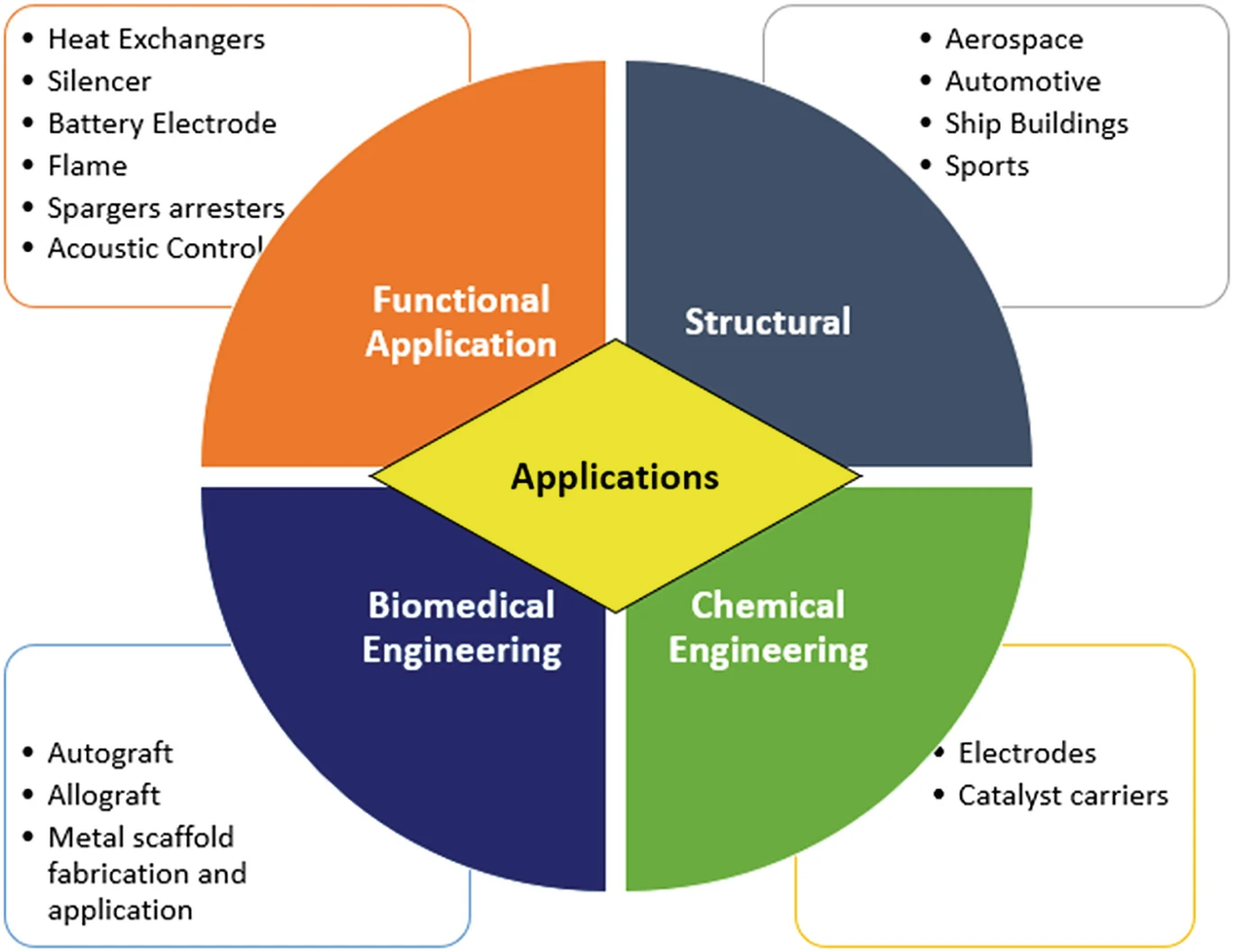

Metallic Foams in Bone Tissue EngineeringSomasundaram Prasadh, Sreenivas Raguraman, Raymond Wong, and 1 more authorIn Nanoscale Engineering of Biomaterials: Properties and Applications, Jun 2022

Metallic Foams in Bone Tissue EngineeringSomasundaram Prasadh, Sreenivas Raguraman, Raymond Wong, and 1 more authorIn Nanoscale Engineering of Biomaterials: Properties and Applications, Jun 2022Bone defects occur due to factors such as congenital anomaly, trauma, and osseous deficiency following resection of tumours. Biomaterials are required for bone augmentation of the lost bone architecture. Clinicians attempting to regenerate the tissue and restore its function and aesthetics because of trauma, pathology, or congenital defects face a substantial challenge. The concept of using metallic foam in bone tissue engineering is a key factor in the regeneration of critical size bone defects. Significant research efforts have been dedicated to the development of metallic foams for bone tissue engineering due to their suitable mechanical and biological properties. Although, at present, most of the studies are focused on non-load bearing materials, many materials are also being investigated for hard tissue repair. Several biocompatible metallic foam materials such as titanium alloys, tantalum, iron, zinc, and magnesium alloys have been commonly employed as implants in biomedical applications. They are often used to replace and regenerate the damaged bones or to provide structural support for healing bone defects. The bone cells develop on the porous regions of the implants. These cells develop over the surface of the foam, which imparts the integrity and strength. The scaffolds help in regeneration of the biological structural components of the extracellular matrix. This chapter focuses on the commonly used metallic foams for bone tissue engineering, their properties, applications, and cellular interactions.

2020

-

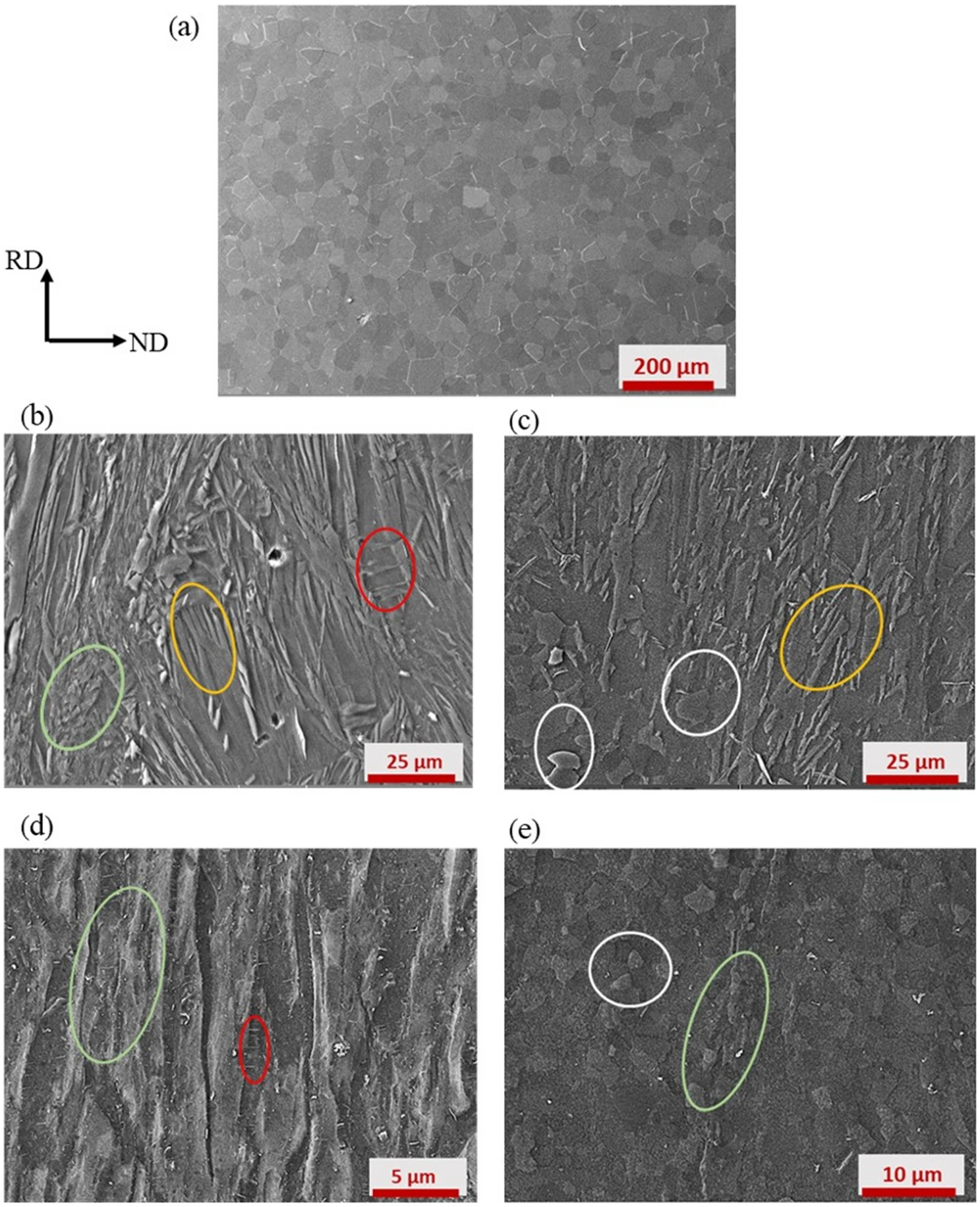

Development of Recrystallization Texture in Commercially Pure Titanium: Experiments and SimulationGyan Shankar, Sreenivas Raguraman, Luis A. Barrales-Mora, and 1 more authorJOM, Dec 2020

Development of Recrystallization Texture in Commercially Pure Titanium: Experiments and SimulationGyan Shankar, Sreenivas Raguraman, Luis A. Barrales-Mora, and 1 more authorJOM, Dec 2020The recrystallization behaviour of cold-rolled (CR) commercially pure (cp)-titanium was investigated by experiments and simulations. The recrystallization texture in cp-titanium depends upon the deformation texture. The main texture components of the lower deformed (50% CR) material are 1014 < 2131 >, 1013 < 2131 > and1235 < 2311 >, all having weak intensity, and in the case of 70% cold rolling the texture component is 1013 < 3031 >. For the simulations, a parallel 3D cellular automata (CA) model for recrystallization was employed. The simulation results showed good agreement with the recrystallization kinetics, grain size distribution, microstructure and texture. The mechanism of recrystallization and the evolution of recrystallization texture were found to depend on the site of nucleation, i.e., whether it is formed at grain boundaries, within the grain, in the lath region or in the highly deformed region such as shear bands.